Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

News Center

Introduction of Industrial Camera in Machine Vision

Publish:

2023-03-14 10:07

Source:

Premier-Cable.net

Industrial cameras are divided into analog cameras and digital cameras. The digital interface transmits digital signals, while the analog interface transmits analog signals. Digital signals have many advantages over analog signals, such as strong anti-interference ability, easy to encrypt, and convenient for subsequent processing. Therefore, today's high-end industrial cameras basically use digital interfaces. However, for the reasons of cost and cost performance, the monitoring equipment at the middle and low end basically adopts analog interface.

Common electrical digital interfaces of industrial cameras include USB interface, IEEE1394 interface, GIGE interface, Camera Link interface, Hirose interface, HDMI interface, VGA and other special interfaces. Now, follow our Premier Cable to lear more.

1. USB interface

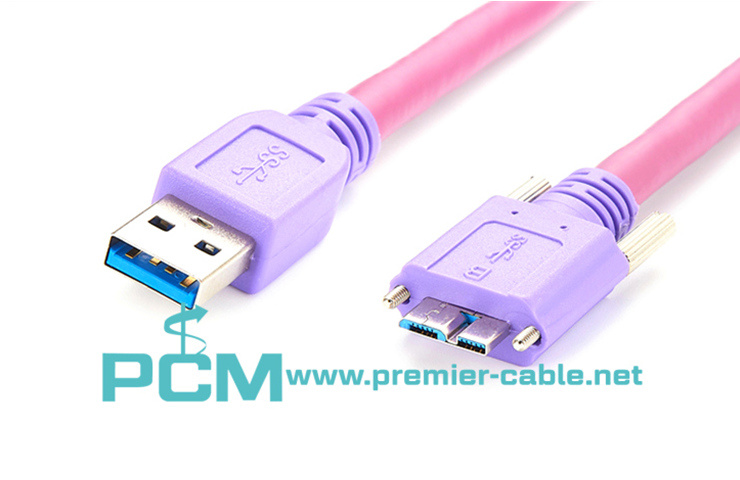

Industrial camera with USB2.0 interface is the most common type at present. Industrial camera with USB 2.0 interface is a common type in the market. Many manufacturers produce cameras with this interface. Its advantages are that all computers are equipped with USB 2.0 interface, which is convenient for connection, and no acquisition card is required. The camera can be powered by USB cable; The disadvantage is that its transmission rate is relatively slow, and the theoretical speed is only 480Mb (60MB). Due to its poor protocol (Bulk Only Transport (BOT) protocol) and encoding method, the data is only about 30MB/S.

The design of USB 3.0 adds two sets of data buses on the basis of USB 2.0. In order to ensure downward compatibility, USB 3.0 retains a set of transmission buses of USB 2.0. In terms of transmission protocol, USB 3.0 not only supports the traditional BOT protocol, but also adds USB Attached SCSI Protocol (USAP), which can fully play the advantage of 5Gbps high-speed bandwidth.

2. IEEE1394 interface (FireWire interface)

The 1394 interface is also known as the FireWire interface. 1394 interface is mainly divided into 1394A interface with a speed of 400Mb and 1394B interface with a speed of 800Mb. In the industrial field, it is still widely used. The protocol and coding method are very good, and the transmission speed is relatively stable. However, due to Apple's early monopoly, it has not been widely used. In industry, 400Mb 1394A and 800Mb 1394B interfaces are commonly used. There are more than 800Mb, such as 3.2Gb, but it is rare. The 1394 interface, especially the 1394B interface, has solid screws.

The 1394 interface features hot plugging, point-to-point communication, standard DCAM protocol, low CPU consumption and power supply via 1394 bus. However, since the 1394 interface was not well popularized in the early stage, there is no corresponding interface on the existing PC terminal. If you want to connect the corresponding camera, you need to cooperate with the 1394 interface acquisition card. At present, 1394 interface has been gradually eliminated by the market.

3. GIGE interface

GIGE is a camera interface standard developed based on Gigabit Ethernet communication protocol. It is suitable for industrial imaging applications and transmits uncompressed video signals through the network. Even if the hardware and software of different manufacturers meet the GigEVision standard, seamless gigabit network connection can be achieved. The industrial camera with gigabit network interface is currently the main camera interface due to the stability of GigE gigabit network protocol.

Some industrial camera manufacturers use M12X-coded 8-core connector interface to provide enhanced shielding and improve the waterproof effect of the equipment. The M12X-coded8P connector replaces the traditional GJ45 interface of Gige on high-end industrial cameras, increasing the bandwidth of Gige to 10Gbit/s. At present, the M12X-coded 8P interface of 10GigE has gradually become the mainstream interface for fast connection.

4. Camera Link interface

CameraLink standard is a digital image signal communication interface protocol launched in 2000, which is a serial communication protocol. The protocol adopts MDR-26-pin connector or SDR-26-pin connector, which is characterized by high speed, bandwidth up to 6400Mbps, strong anti-interference ability and low power consumption. The basic standard uses MDR ("MiniDRibbon") 26-pin connector.

There are few cameras with Camera Link interface in practical applications. However, its transmission speed is the fastest bus type in the current industrial camera. It is generally used for high-resolution high-speed area array camera or linear array camera.

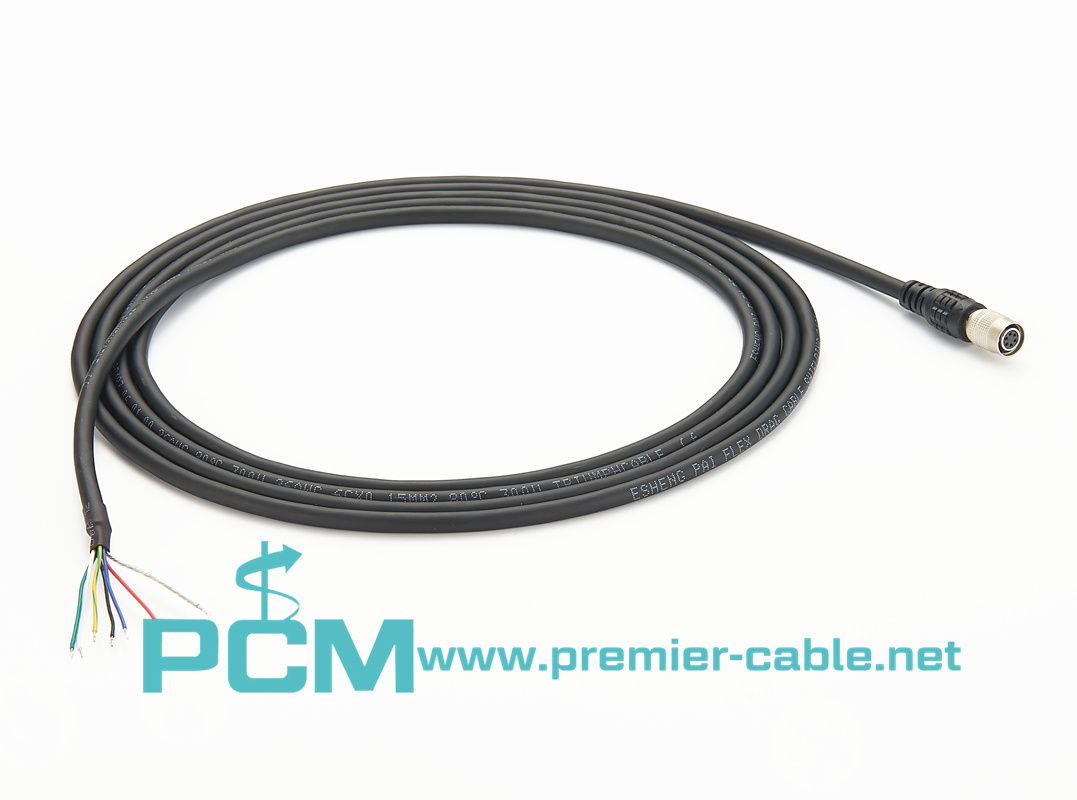

5. Special interface

Some manufacturers use special interfaces/connectors in pursuit of product differentiation or product use environment. A common special interface (power interface or I/O interface) on industrial cameras is Hirose Hirose's connector, which has 6 cores (HR10A-7P-6S) and 12 cores (HR10A-10P-12S). It is generally used for external power supply and control of Gige industrial cameras.

There are also M12 D-coded buckle/coding 4-core connectors used as I/O interfaces on 3D smart cameras, and M12A-coded buckle/coding/coding 8-core, 12-core and 17-core connectors used as power interfaces on smart industrial cameras.

There are also some less common interfaces, such as Ramolemo's push-pull self-locking connector and HDMI, VGA, RS232 and other interfaces.

Premier Cable provides a series of industrial camera cable harnesses suitable for various environments, and its rich product series provides customers with multiple choices for different applications. You can find different machine vision industrial camera connectors here: Micro USB2.0, Mini USB2.0, USB2.0 Type A, Micro USB3.0, USB3.0 Type A, USB3.1 Type C, IEEE1394 FireWire, MDR POCL Camera Link, GIGE RJ45, Hirose HR10A IO Power Cable, M12 to RJ45 Machine Vision Camera Cable.

If you are interested in our products, solutions and services, please leave a message or email us.

Related News

What is a terminal block used for?

While there are many factors to consider when designing an overall system, terminal blocks are an optimal solution for complex electrical system connections. With a variety of color options and configurations, Premier Cable’ terminal blocks offer a range of options to meet your design challenges.

CAN-bus has been widely used in various automation control systems. For example, CAN-bus has incomparable advantages in various fields such as automotive electronics, automatic control, smart buildings, power systems, and security monitoring.

Introduction to M12 connector pin coding

M12 encoding types are A encoding, B encoding, D encoding and X encoding. A-code, B-code and X-code are some of the earliest developed and longest-available M12 connectors. The latest M12 coding types currently under development are K coding for AC and L coding for PROFINET DC.

Cables – What are the correct cable sizes for an NMEA 2000 network?

The three different sizes of NMEA 2000 certified DeviceNet standard cabling are "micro," "mid," and "mini."

What are the advantages of NMEA 2000?

The Premier Cable Starter Kits provide everything you need to get to create a basic NMEA 2000 network from scratch.

The role of DeviceNet terminal resistor

DeviceNet_network is a fieldbus network protocol based on Controller Area Network (CAN). In the DeviceNet network, the terminal resistor plays the role of compensation and protection for signal transmission. The function of the terminal resistor is to eliminate signal reflection and interference and ensure the signal transmission quality.