Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

News Center

Frequency Converter's Function

Publish:

2023-03-08 09:58

Source:

Frequency converter is a power control equipment that uses frequency conversion technology and microelectronics technology to control AC motor by changing the frequency of motor working power supply.

Working principle of frequency converter

The frequency inverter is mainly composed of rectifier (AC to DC), filter, inverter (DC to AC), braking unit, driving unit, detection unit, micro-processing unit, etc. The frequency converter adjusts the voltage and frequency of the output power supply by switching off the internal IGBT, and provides the required power supply voltage according to the actual needs of the motor to achieve the purpose of energy saving and speed regulation. In addition, the frequency converter has many protection functions, such as overcurrent, overvoltage, overload protection, etc. With the continuous improvement of industrial automation, frequency converters have also been widely used, such as fans, pumps, elevators, etc., playing a vital role.

The main circuit is the power conversion part that provides voltage regulation and frequency modulation power for the asynchronous motor. The main circuit of the frequency converter can be divided into two types: the voltage type is the frequency converter that converts the DC of the voltage source to the AC, and the filter of the DC circuit is the capacitor. Current mode is a frequency converter that converts the DC of current source into AC, and its DC circuit filter is inductance. It is composed of three parts: a "rectifier" that converts power frequency power into DC power, and a smoothing circuit that absorbs the voltage ripple generated by the converter and inverter.

Function of frequency converter

1. Energy-saving function of frequency converter

One of the biggest advantages of frequency converter is energy saving. The most obvious industry is the application of fan and pump industry. Because the power consumption of the fan and pump is proportional to the cube of the rotating speed, when the external air/water consumption is not high, using frequency conversion to reduce the rotating speed will have obvious energy-saving effect. The principle of energy saving in other industries is probably the same. It is achieved by reducing the motor speed when it is not necessary to run at full speed.

2. Soft start function of frequency converter

When the motor is started by direct air at power frequency, it will generate 7 to 8 times of the rated current of the motor. The increase of the current increases the electrical stress of the motor winding and generates heat, thus reducing the service life of the frequency converter. The variable frequency speed regulation can be started at zero speed and zero voltage (or torque lifting can be appropriately added).

3. The function of converter control system simplification

Variable frequency speed regulation can be started at zero speed and accelerate uniformly according to the user's needs, and its acceleration curve can also be selected (linear acceleration, S-shaped acceleration or automatic acceleration). The running speed can be adjusted at any time according to the needs, and can be changed rapidly according to the technological process. The speed can also be changed by remote control PLC or other controllers.

4. The function of frequency converter to reduce mechanical wear and loss

When starting at power frequency, it will cause severe vibration to the motor or the shaft or gear of the connected mechanical part. This vibration will further aggravate mechanical wear and loss, and reduce the service life of mechanical components and motors. In the variable frequency speed regulation, the stop mode can be controlled, and different stop modes can be selected (deceleration stop, free stop, deceleration stop+DC brake). It can reduce the impact on mechanical components and motors, thus making the whole system more reliable, and the service life will also increase accordingly, while improving the system stability.

5. Adjustable torque limit function of frequency converter

The corresponding torque limit can be set after variable frequency speed regulation to protect the machinery from damage, thus ensuring the continuity of the process and the reliability of the product. The current frequency conversion technology makes not only the torque limit adjustable, but also the torque control accuracy can reach about 3%~5%. In the power frequency state, the motor can only be controlled by detecting the current value or thermal protection, but it can not operate by setting accurate torque value as in the frequency conversion control.

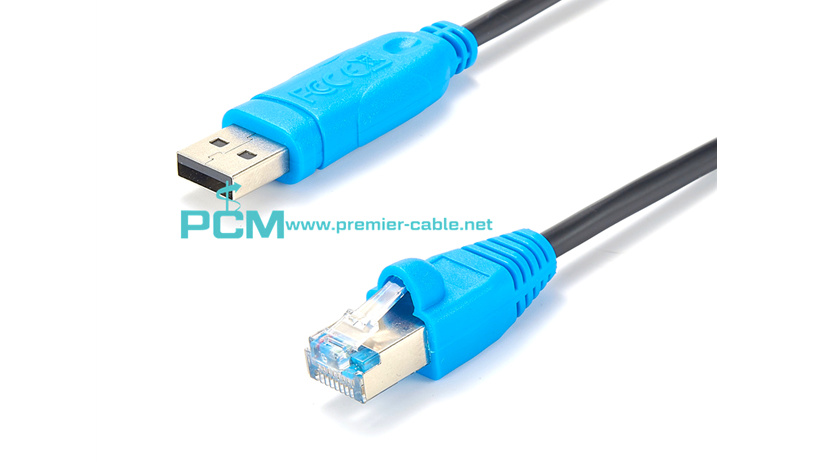

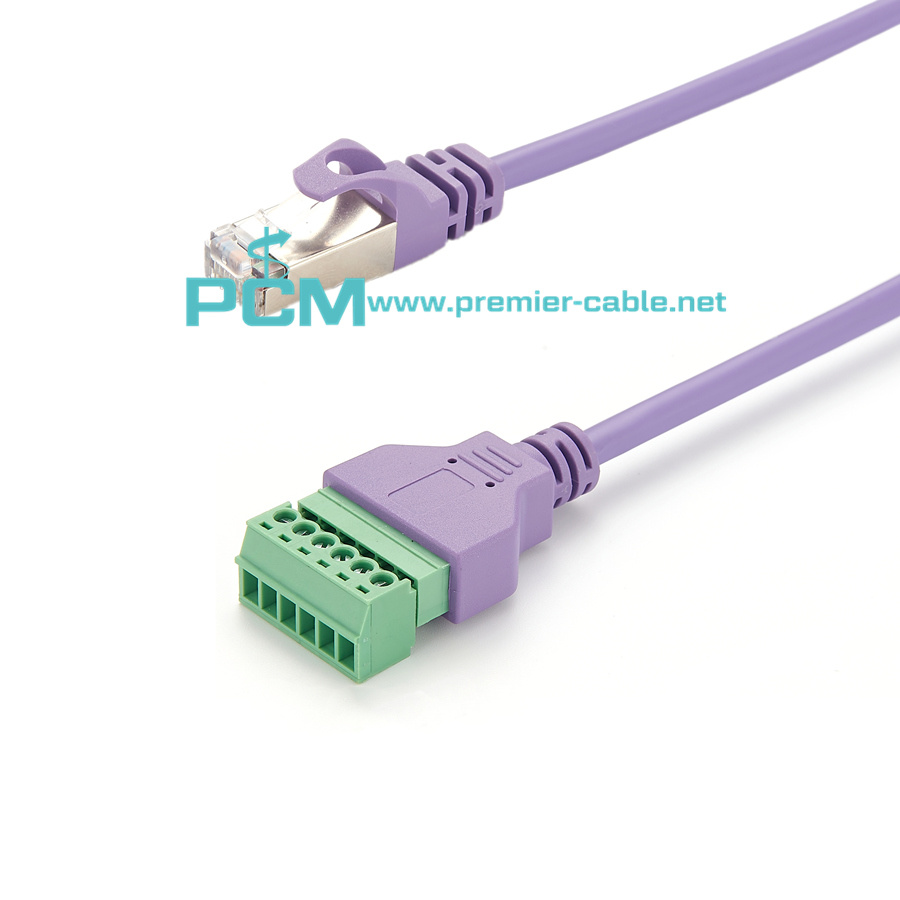

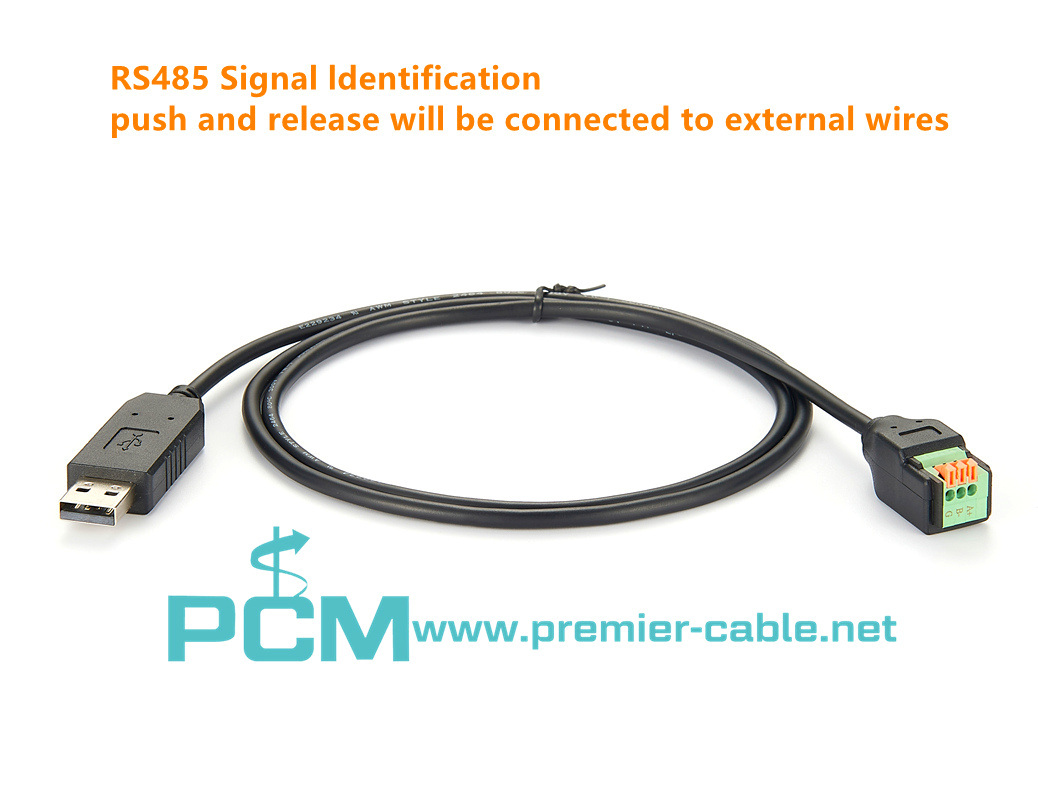

The frequency converter control system can realize speed change through remote control PLC or other controllers, which requires high-quality communication control cable. Premier Cable provides RS485 frequency inverter cable, Modbus communication RJ45 to USB cable, Solar Controller Cable USB RS485 and other different serial cable harnesses.

Our Premier Cable make the cable assemblies & harness to Energy System. And it is widly used for Solar Panels, Inverters, Generators, Batteries, UPS, Servers, Electric Meters, Controller Communication, and CANBus Modbus. Welcome to leave us message for your customized.

Related News

What is a terminal block used for?

While there are many factors to consider when designing an overall system, terminal blocks are an optimal solution for complex electrical system connections. With a variety of color options and configurations, Premier Cable’ terminal blocks offer a range of options to meet your design challenges.

CAN-bus has been widely used in various automation control systems. For example, CAN-bus has incomparable advantages in various fields such as automotive electronics, automatic control, smart buildings, power systems, and security monitoring.

Introduction to M12 connector pin coding

M12 encoding types are A encoding, B encoding, D encoding and X encoding. A-code, B-code and X-code are some of the earliest developed and longest-available M12 connectors. The latest M12 coding types currently under development are K coding for AC and L coding for PROFINET DC.

Cables – What are the correct cable sizes for an NMEA 2000 network?

The three different sizes of NMEA 2000 certified DeviceNet standard cabling are "micro," "mid," and "mini."

What are the advantages of NMEA 2000?

The Premier Cable Starter Kits provide everything you need to get to create a basic NMEA 2000 network from scratch.

The role of DeviceNet terminal resistor

DeviceNet_network is a fieldbus network protocol based on Controller Area Network (CAN). In the DeviceNet network, the terminal resistor plays the role of compensation and protection for signal transmission. The function of the terminal resistor is to eliminate signal reflection and interference and ensure the signal transmission quality.