Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

News Center

Electronic Manufacturing Service

Publish:

2022-07-20 15:52

Source:

www.premier-cable.net

Electronic Manufacturing Service

EMS factory is an electronic manufacturing service factory, which is commonly referred to as an electronic factory

Most factories have production lines consisting of large machines or equipment, The concept is also referred to as Electronics Contract Manufacturing ECM

In modern world history, it generally refers to capitalist machine production, that is, capitalist industrial sites that use mechanized labor instead of manual labor.

Modern’s factories are also called “manufacturing plants” and “production enterprises”

EMS : Abbreviation of Electronic Manufacturing Services, that is, electronic manufacturing services, electronic professional manufacturing services, also known as ECM, Chinese also translated as professional electronic foundry services, is an emerging industry, it refers to the provision of manufacturing, procurement, part of the electronic product brand owners.

Manufacturer of a series of services such as design and logistics.

Compared with traditional OEM or ODM services that only provide product design and OEM production, EMS manufacturers provide knowledge and management services, such as material management, logistics transportation, and even product maintenance services.

In fact, the production process involves many processes and links. EMS is a full-line service, including product development, product production, which of course includes product procurement, product quality management, and transportation logistics. Generally, EMS includes the above.

There are ems factories in many industries, not only in industries that require precision manufacturing, but also in traditional manufacturing, more and more ems factories appear.

The emergence of this kind of factory is a good thing for capital, it can create more value per unit time, and it can also reduce the use of manpower, which is a very good choice for cost saving.

There are many jobs in modern industrial development that cannot be easily completed by manpower, or cannot be completed at all. For example, the overall assembly of automobiles needs to be completed with the cooperation of large machines.

The continuous development of the electronics industry has made it possible to use electronically controlled machines to work in these industries.

When the ems factory first started, it was originally designed to reduce the harm to workers in some positions that are harmful to the human body. Later, with the advancement of technology, electronic machines can not only reduce serious injuries to workers, but also can be done in some manufacturing processes than manual ones. Better, so many industries began to use electronic machines a lot.

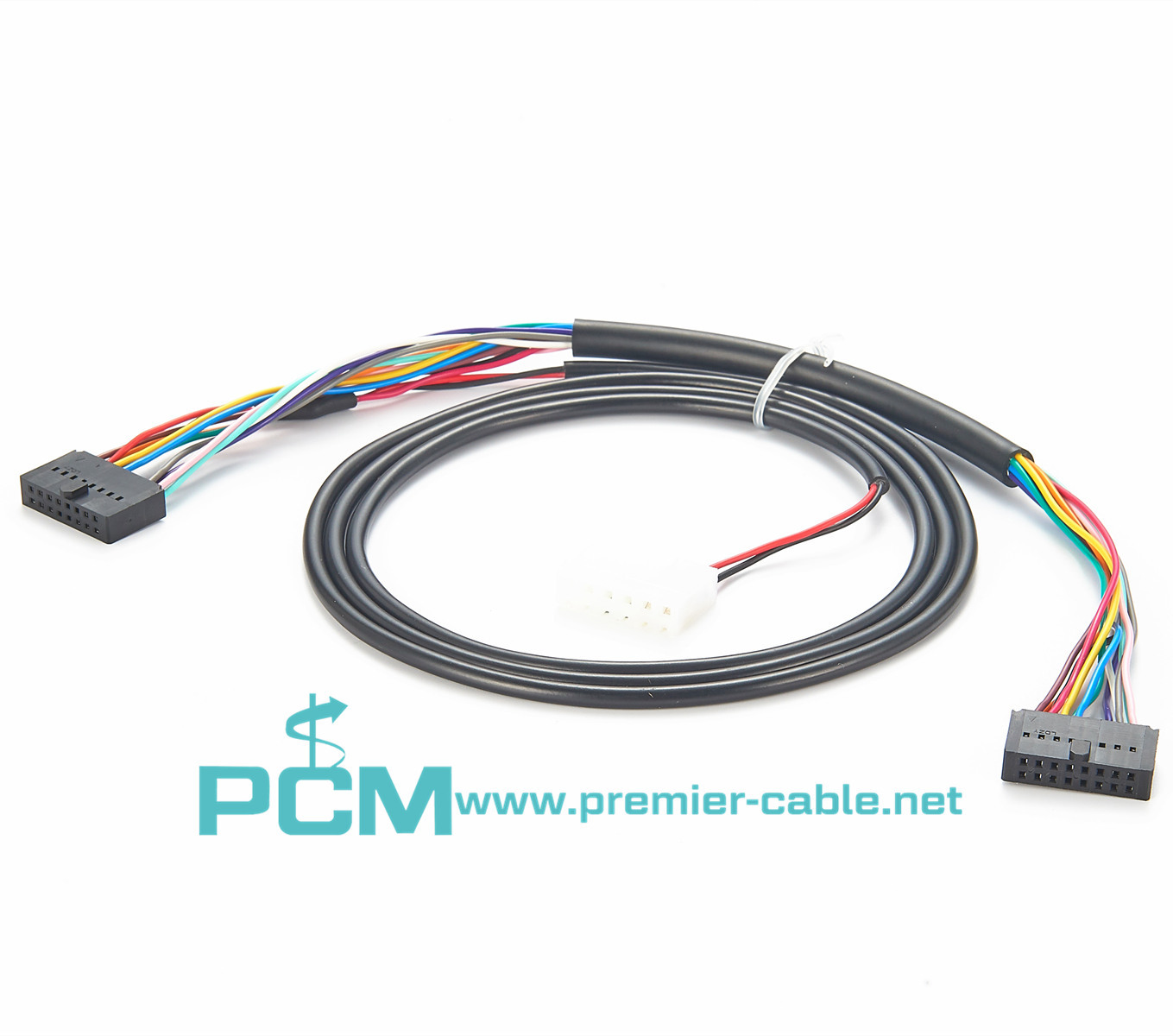

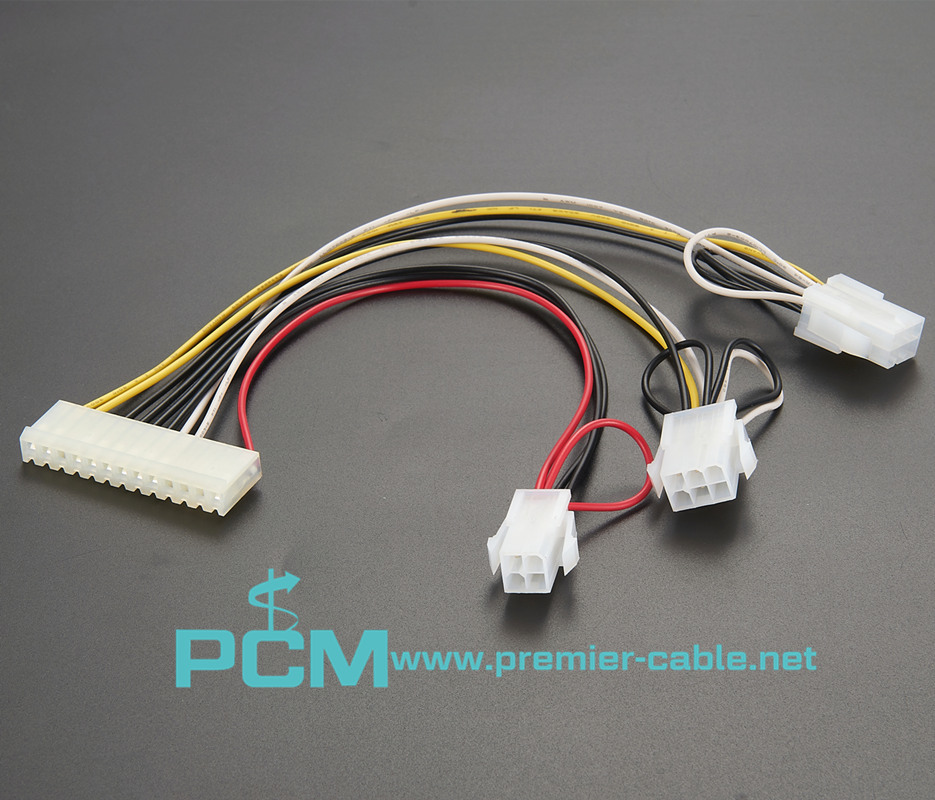

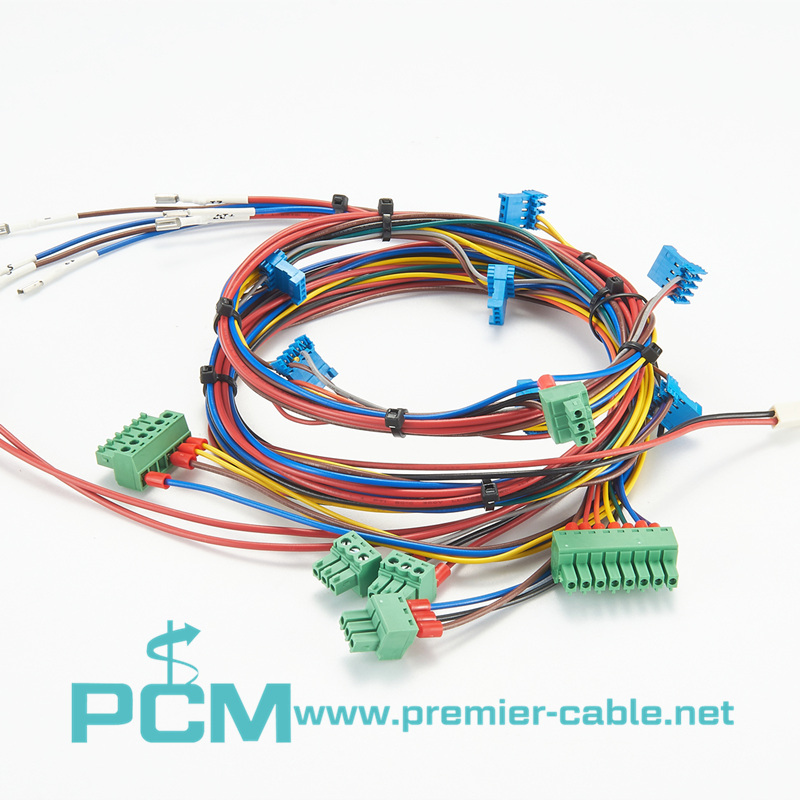

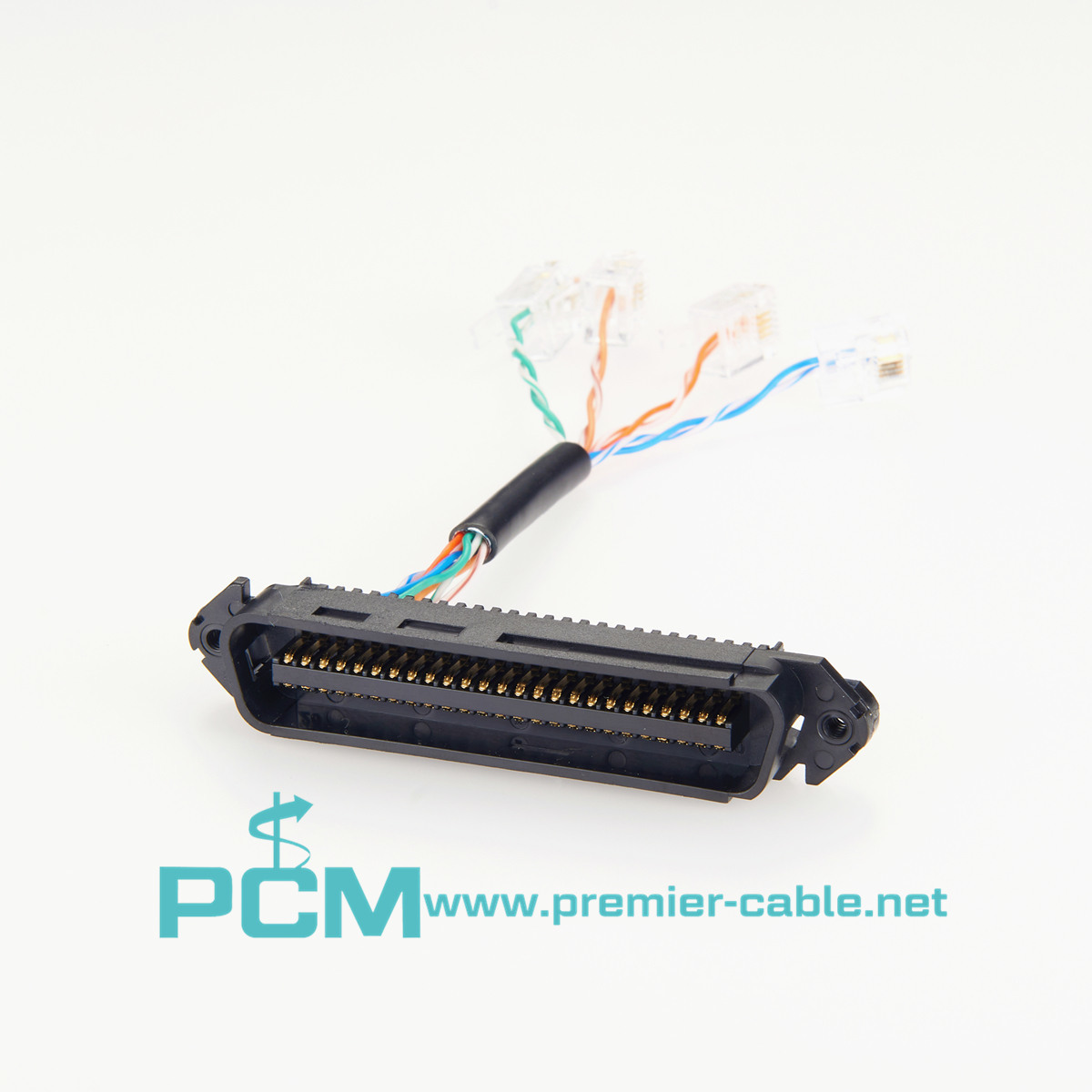

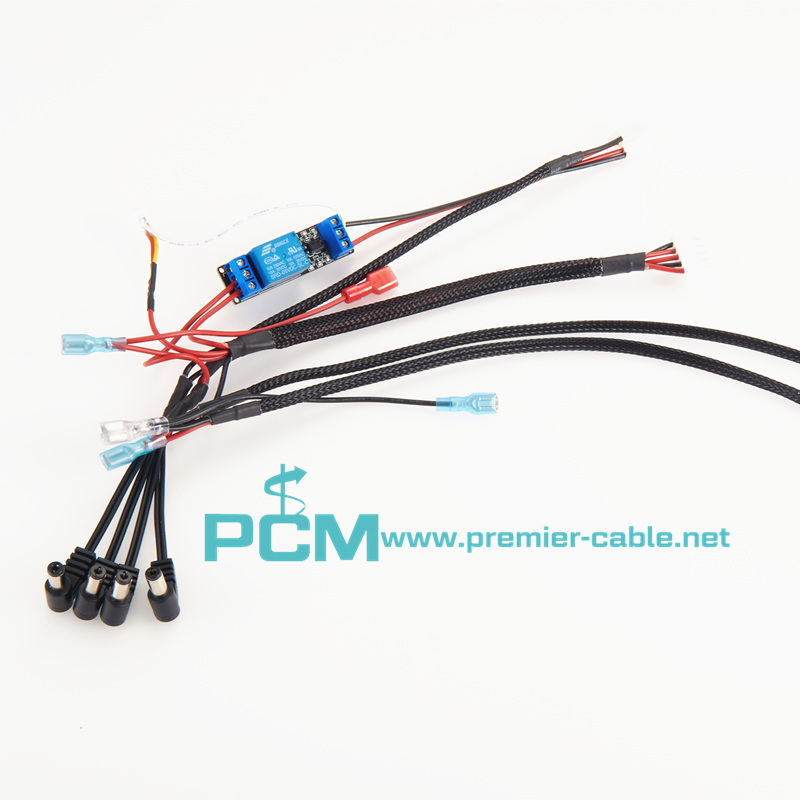

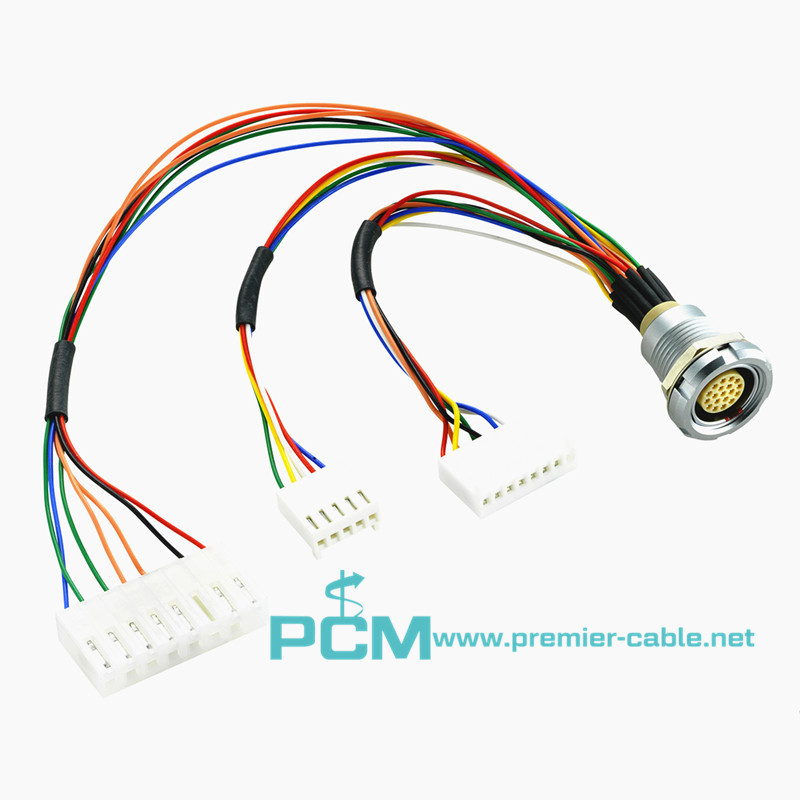

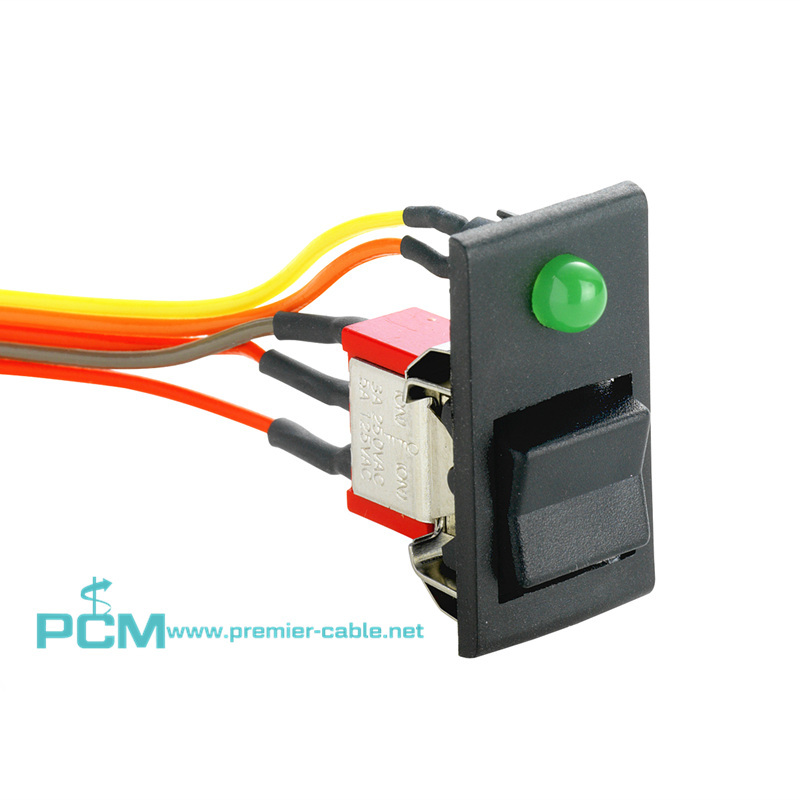

Premier Cable Co. Ltd, www.premier-cable.net, is a cable factory with 400 workers , we make a lot of Cable Assemblies and wire harness

We accept OEM and ODM service, we serve the cables for below industries :

Electronics Box Build

Molex Cable Assembly

Custom Cable Assembly

Box Build Cable Assemblies

Control Box Cable Assembly

Control Panel Cable Assembly

EMBEDDED SYSTEMS DESIGN

Touch Screen for Raspberry Pi

Touch screen display solutions

Panel Wiring Cable Assemblies

Self Service Kiosk Manufacturer

Molex Custom Cable Assembly

Box-Build System Assembly

SMT & Box build Technology

Custom PCB Assembly Services

self-service terminal technologies

Raspberry PI Display and Volumio

Printed circuit board Cable assembly

Electro- Mechanical Cable Assemblies

Electronic Manufacturing Services

Electronics Contract Manufacturers

Original Equipment Manufacturers

Electronic Components Manufacturers

Electronic Manufacturing Companies

Electronic Manufacturing Services EMS

Electronics Contract Manufacturing EMS

Military Wire Harnesses & Cable Assemblies

Printed Circuit Board Manufacturing & PCB Assembly

Industrial design company specialising in self-service terminal technologies

Tel : 0086-0139-2949-7934

Skype : james198585

Email : James@premier-cable.net

Email : sales@premier-cable-mfg.com

Related News

What is a terminal block used for?

While there are many factors to consider when designing an overall system, terminal blocks are an optimal solution for complex electrical system connections. With a variety of color options and configurations, Premier Cable’ terminal blocks offer a range of options to meet your design challenges.

CAN-bus has been widely used in various automation control systems. For example, CAN-bus has incomparable advantages in various fields such as automotive electronics, automatic control, smart buildings, power systems, and security monitoring.

Introduction to M12 connector pin coding

M12 encoding types are A encoding, B encoding, D encoding and X encoding. A-code, B-code and X-code are some of the earliest developed and longest-available M12 connectors. The latest M12 coding types currently under development are K coding for AC and L coding for PROFINET DC.

Cables – What are the correct cable sizes for an NMEA 2000 network?

The three different sizes of NMEA 2000 certified DeviceNet standard cabling are "micro," "mid," and "mini."

What are the advantages of NMEA 2000?

The Premier Cable Starter Kits provide everything you need to get to create a basic NMEA 2000 network from scratch.

The role of DeviceNet terminal resistor

DeviceNet_network is a fieldbus network protocol based on Controller Area Network (CAN). In the DeviceNet network, the terminal resistor plays the role of compensation and protection for signal transmission. The function of the terminal resistor is to eliminate signal reflection and interference and ensure the signal transmission quality.